JUKI PLK-G2008H-NB COMPLETE ASSEMBLY

Description / JUKI PLK-G2008H-NB COMPLETE ASSEMBLY

Juki PLK-G2008H

- 200 x 80mm: Computer-controlled Cycle Machine with Input Function.

Machines created to improve work efficiency. The 'G' series is equipped with a function for programming the presser foot height to avoid skipped stitches and thread breaks. Equipped with 750W direct servo motor, this series realizes one of the strongest needle penetration forces in the industry. Features and functionalities used are designed to facilitate work and ensure the highest quality results.

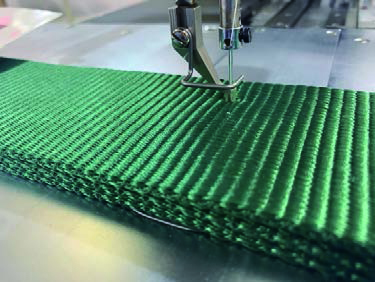

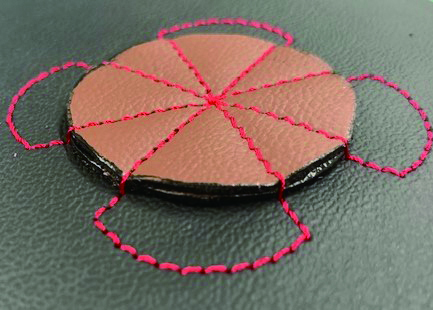

Beautiful stitches

Improvements to the rigidity of the presser foot mechanism and feed mechanism coupled with the latest feed control (feedback control) ensure beautiful and accurate stitches from low to high speed, such as for corners and straight seam lines according to sewing data. In addition, the use of both rotary and shuttle hooks provides stable stitching depending on the fabric that is sewn.

Powerful needle penetration force

Equipped with an improved 750W direct servo motor, this series realizes one of the strongest needle penetration force in the industry. Stitching can be performed easily even at low speeds (200 sti/min*) for thread trimming and start of stitching, which are conventionally difficult.

* sti/min is the abbreviation for “stitches per minute”

Programmable presser foot height control

This series is equipped with a function for programming the presser foot height. Changing the presser foot height according to the thickness of the material can prevent skipped stitches and thread breaks. The programmed presser foot height is stored in the stitching data; therefore, the presser foot height does not need to be adjusted even if the thickness of the material varies by the stitching pattern.

Improved work efficiency

Use of USB memory and a high-speed processing system greatly reduces the time required to input and correct pattern data with a large number of stitches, which used to be time consuming. In addition, the jog key ensures speedy clamp movement for improved work efficiency.

Compatible with extra-thick materials (equipped with an extra-thick thread trimmer)

This is ideal for stitching safety belts, suspension fittings, and sling belts for lifting. Thread fraying is prevented by an extra-thick needle thread and bobbin thread trimmer that uses a heat cutter.

Technical Specification

| Model name | Juki PLK-G2008H |

|---|---|

| Stitching style | Single-needle lockstitch |

| Hook | Special semi-rotation hook (with bobbin removal mechanism) |

| Needle | 794 #230 |

| Max. speed (Note 1) | Intermittent feed 700 sti/min*, Continuous feed 700 sti/min* |

| Feeding system | Intermittent or continuous (switchover method) * Intermittent recommended |

| Stitch length | 0.1 to 20.0mm (min. resolution 0.1mm) |

| Max. stitches | 20,000 stitches/pattern |

| Max. patterns (Note 2) | 900/internal memory |

| Memory medium | USB flash memory (not provided with sewing machine) (USB-connected floppy disk drive may also be used) |

| Work holder | Pneumatic |

| Zoom function | 10 to 200% per X/Y axis (variable by 0.1% step) |

| Outer presser foot lift stroke | Max. 20mm |

| Thread cutting system | Heat cut system |

| Presser foot lift stroke | 25mm |

| Main shaft motor | XL-G554-20(Y) |

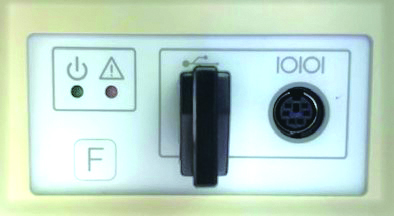

| Operation panel | 5.7-inch LCD touch panel, white LED backlight |

| Outline dimensions | 1,200 x 780 x 1,320mm (WxDxH) (not including thread stand) |

| Mass | 172kg |

| Power supply | 200 to 240V single-phase/three-phase |

Note 1: Sewing speed may be limited by the type of sewing material, presser weight, stitch length, etc.

Note 2: Max. patterns may be limited depending on the number of stitches per pattern in the memory.

* sti/min is the abbreviation for “stitches per minute”

More Information

| Part No | PLKG2008H |

|---|---|

| Weight (KG) | 0.100000 |

| Manufacturer | Juki |