JUKI MB-1800B COMPUTER CONTROLLED CHAINSTITCH BUTTON SEWING MACHINE

Description / JUKI MB-1800B COMPUTER CONTROLLED CHAINSTITCH BUTTON SEWING MACHINE

Juki MB-1800B

Computer-controlled, Dry-head, High-speed, Single-thread, Chainstitch Button Sewing Machine (with Wiper Unit)

A new button sewing machine that supports many different button sewing specifications independently.

Excellent seam quality and improved flexibility

It comes with direct-drive electronic feed driven by a compact AC servomotor to guarantee excellent seam quality and dramatically improve flexibility and maintainability.

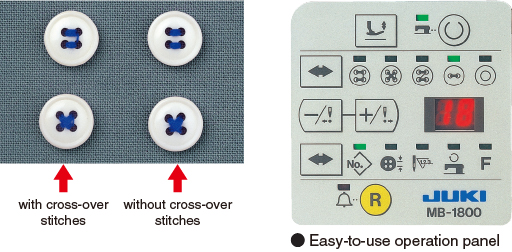

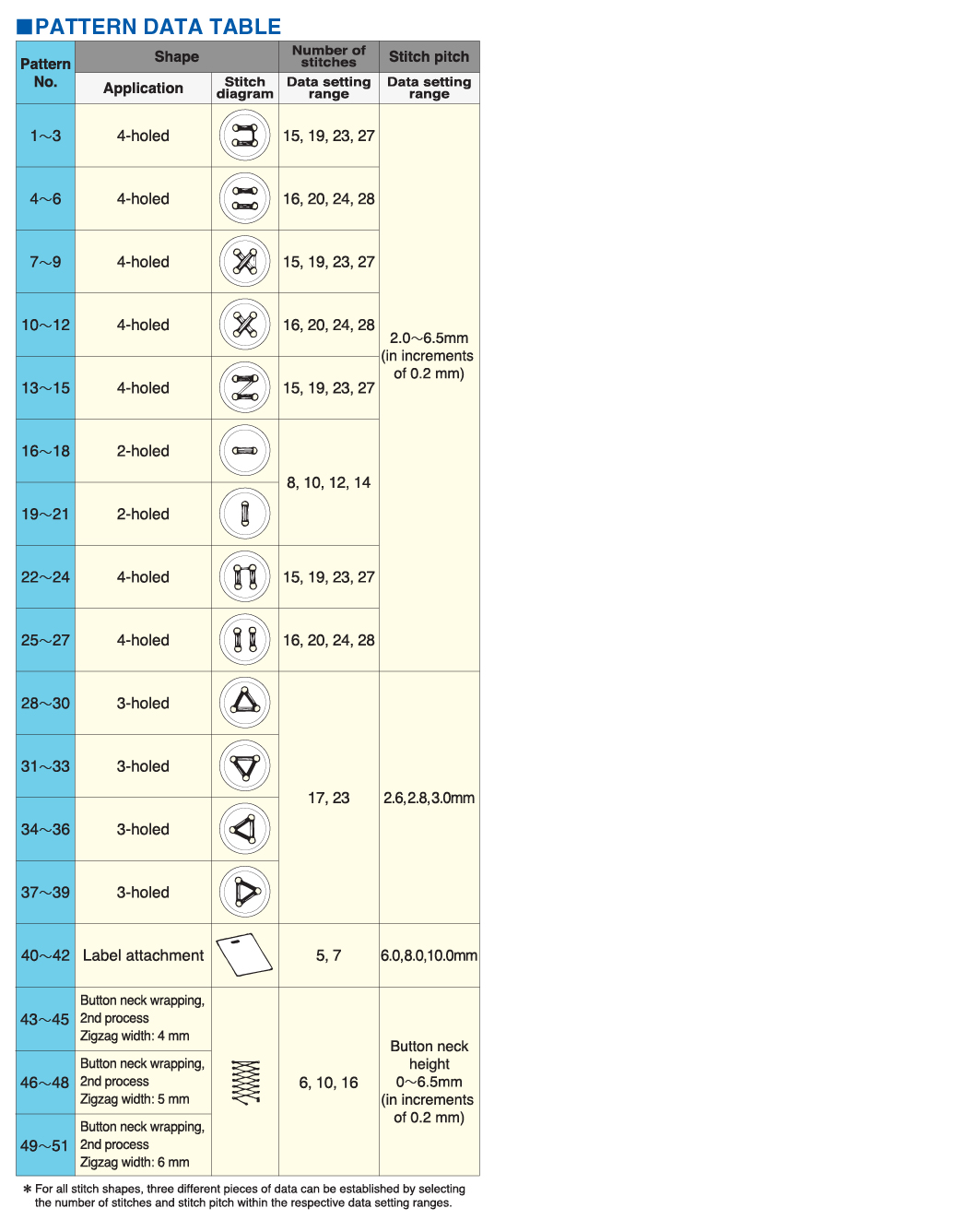

The machine is able to independently sew various stitching shapes such as U-shaped stitching, X-shaped stitching and Z-shaped stitching

The machine has 55 different stitching patterns as standard. In addition to the sewing shapes, the buttonhole intervals and number of stitches can also be changed on the operation panel. The machine completely supports many different button specifications to increase its range of applicability, reduce costs associated with changes in specifications, and save the operator from having to adapt the machine to different specifications.

Custom patterns can be created on the PGM-20 and then used on the sewing machine.

Shorter lengths of thread remain after thread trimming

The machine performs thread trimming at the optimal position by correcting the button position with respect to the needle entry of the last stitch. This shortens the thread remaining on the material after thread trimming to approx. 3.5 mm.

The dry-head eliminates oil stains

The machine head is a non-lubricating type. With this type, the operator never has to add oil, and staining of the sewing product with oil is an impossibility.

The machine sews buttons with beautifully finished seams

The machine adopts a stitching pattern with the tying stitch only at the final stitch. This ideal stitching pattern optimizes single thread chainstitching to produce beautiful seams on the wrong side of the material, thereby guaranteeing excellent seam quality.

Moreovers, since the machine uses significantly fewer mechanical parts, troubles caused by excessive play in the feed such as needle breakage and button breakage occur for less often.

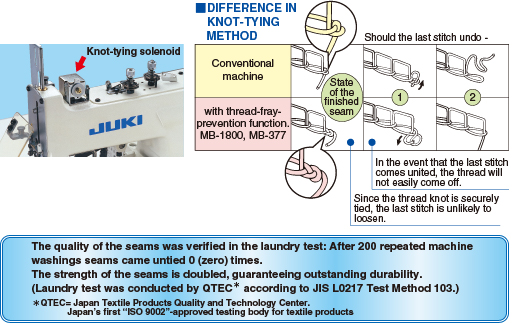

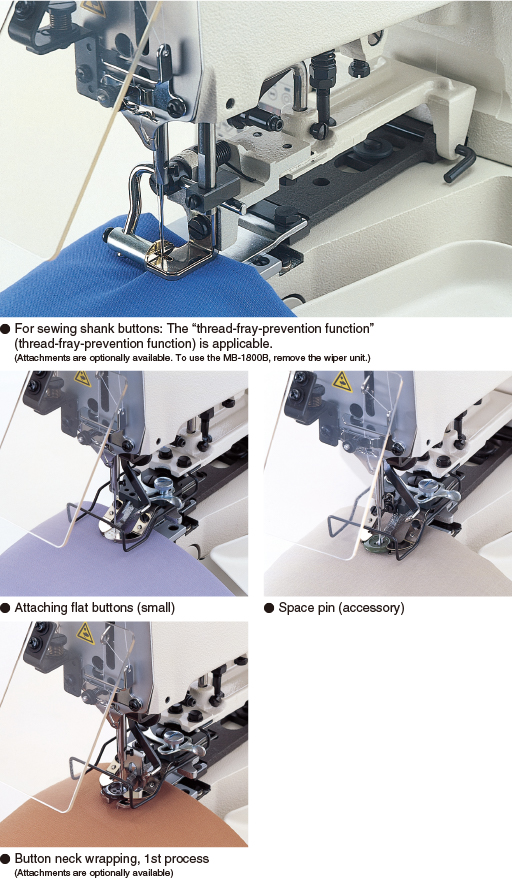

The machine is equipped as standard with thread-fray-prevention function

The machine comes as standard with the solenoid-operated, thread-tension-changeover "thread-fray-prevention function." Since the machine is designed to use a long needle (TQ×7), the "thread-fray-prevention function" can be used for sewing shank buttons.

The "thread-fray-prevention mechanism" can be rendered ON or OFF as required by setting the solenoid drive ON or OFF.

The machine offers outstanding productivity

The machine runs at a maximum sewing speed of 1,800 rpm and comes with a direct-drive system supported by a compact AC servomotor that offers excellent stopping accuracy and responsiveness. Working in combination, these features shorten the machine time by 10 % or more compared with our conventional machine.

Needless to say, the single-thread, chainstitch, button sewing machine does not need bobbin thread changing.

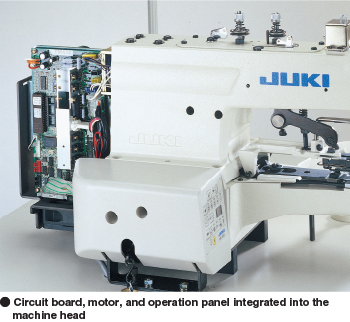

Excellent maintainability and operability

Thanks to the elimination of the mechanical structures such as the stop-motion mechanism and feed cam, the machine operates with less vibration and noise and requires no maintenance.

The foot pedal can be operated with reduced pressure from the operator's foot. This helps reduce operator fatigue by allowing the operator to operate the machine more rhythmically.

The machine responds to many different button sewing specifications

Technical Specification

| Model name | Juki MB-1800B |

|---|---|

| Max. sewing speed | 1,800rpm |

| Amount of feed | Crosswise feed 0~10mm • Lengthwise feed 0~6.5mm |

| Applicable buttons | Type : Round-shaped flat buttons Size : φ10~φ28mm Attachment : For small buttons (φ10~φ12mm) For medium buttons (φ12~φ20mm) For large buttons (φ20mm or more) Thickness: 1.8~5mm The button clamp jaw lever for thick buttons has to be used for buttons with thicknesses of 3.5mm or more |

| Type : Shank buttons, wrapped-around buttons, snaps, metal buttons, stay buttons, labels (exclusive attachments have to be used.) | |

| Stitching shape |  |

|

|

| Wiper unit | Provided as standard |

| Lift of the button clamp | Max. 14mm |

| Needle bar stroke | 48.6mm |

| Needle (at the time of delivery) | TQ×7(#16) #14~#20 |

| Feed system | By stepping motor |

| Knot-tying mechanism | Provided as standard |

| Lubrication | No lubrication |

| Discrimination of button to be feed | - |

| Button feed | - |

| Button feed mode | - |

| Power requirement | Single-phase 220~240V, 100~120V (by changing over the PWB connector) |

| Power consumption | 150W |

| Weight | Machine head, Circuit board 25kg |

*"sti/min" stands for "Stitches per Minute."

More Information

| Part No | JUKIMB1800B |

|---|---|

| Weight (KG) | 35.000000 |

| Manufacturer | Juki |